When the factory floors are eerily still and the hum of production lines stops, a strange clarity sets in. The clock seems to move quickly, but the hours seem to last forever.

This rare lull isn’t a break for managers and maintenance crews; it’s a narrow window of opportunity where gears can be reset, safety oversights can be found, and dirt can be chased out of corners that never see the light. Failure to address this issue could lead to delays, malfunctions, and increased costs during the next restart.

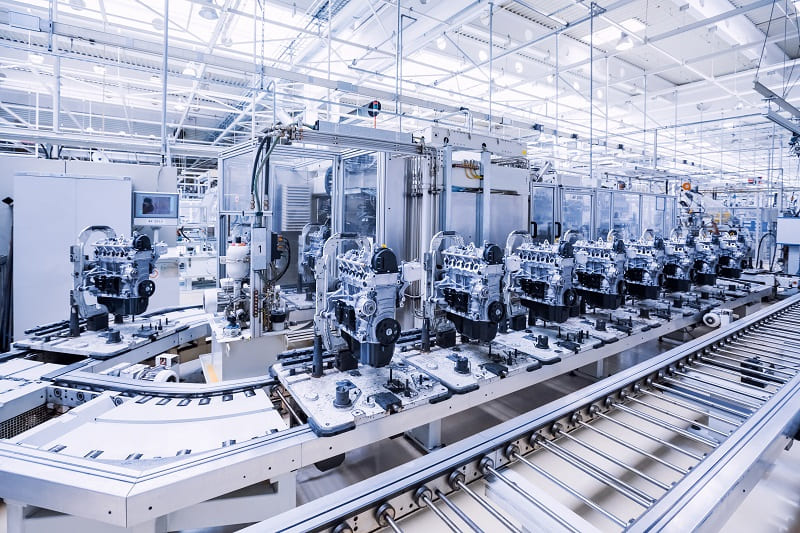

Businesses in the manufacturing, food processing, automotive, and energy sectors use this time to make changes in their operations. With the right plan in place, cleaning up the factory during summer shutdowns does more than just make it look better; it also improves performance, meets safety standards, and gets everything ready for when production starts up again.

Why Industrial Cleaning Matters During a Summer Shutdown

Industrial cleaning during downtime has become a standard practice in modern facilities. The reason is straightforward: accumulated dust, residues, and waste do more than just affect appearance; they impact safety, compliance, and operational reliability.

According to the National Fire Protection Association (NFPA), combustible dust incidents have led to hundreds of workplace fires and explosions over the past decade. In addition, the Occupational Safety and Health Administration (OSHA) consistently cites housekeeping failures as a contributor to accidents.

Downtime also offers access that simply isn’t possible when operations are live. When the equipment is not in use, teams have the opportunity to perform deep cleaning procedures in a safe and controlled manner.

Preparing Your Summer Shutdown Industrial Cleaning Plan

Before any work begins, consider these important preparation steps to keep the cleaning process both safe and efficient:

1. Build Your Team

Start by pulling together a cross-functional team, then give that group a leader, someone accountable for steering the entire shutdown. Bring environmental, health, and safety (EHS) professionals into the fold alongside operations staff and supervisors so that every piece of the process gets the attention it demands.

2. Review Safety and Compliance Programs

Cleaning factories often involves hazardous tasks such as entering small spaces, working with hot materials, and washing with high pressure. Identify activities that require permits, confirm that training is current, and verify compliance with all applicable OSHA regulations.

3. Plan for Waste Management

Every industrial cleaning project produces waste, and improper disposal carries serious consequences. Conduct hazardous waste determinations, stage the correct containers, and review universal waste requirements for items such as lamps, batteries, and aerosols.

For wastewater, facilities must coordinate with local treatment plants to confirm that all discharges meet pretreatment limits.

4. Stage Supplies and Equipment

Confirm that appropriate personal protective equipment (PPE) is available and that the cleaning supplies being used are safe to use with each other. Operators should properly service and set up tools like vacuums, pressure washers, and dry ice blasting units before use.

Areas That Benefit Most from Industrial Cleaning

During a shutdown period teams can access areas that often go unnoticed during daily operations.

– Combustible Dust and Overhead Surfaces

Dust layered on beams, ductwork, and cable trays above the workspace is far more than an eyesore; it’s a hazard waiting for ignition. Removing it cuts the chance of a fire taking hold while making sure that facilities comply with NFPA requirements.

For this work, choose explosion-proof vacuum systems as the standard practice and avoid using compressed air unless a risk assessment proves its use to be safe in that specific environment.

– Machinery and Equipment

Cleaning isn’t just about appearance, as grease, scale, and dirt cling to equipment, choking performance and grinding down its lifespan. Deep cleaning of internal parts, thorough flushing, and targeted degreasing all contribute to maintaining machinery in optimal operating condition.

There must be absolute adherence to lockout/tagout procedures. Zero energy states must be confirmed with every line bled and every valve secured before a single tool makes contact.

– Industrial Cleaning for Cooling Towers and Water Systems

Left unchecked, cooling towers can turn into breeding grounds for bacteria such as Legionella, but thorough cleaning combined with biocide treatment slashes the microbial load and dramatically lowers the risk of contamination spreading through the system.

According to the Centers for Disease Control and Prevention (CDC), facilities that maintain proactive water management programs see fewer Legionella-related issues.

– HVAC and Ventilation Systems

Businesses must comply with a range of rules and regulations, with the use of ventilation systems often being among them. You should regularly check and clean your filters, ducts, and air handling units to make sure that dust, allergens, and other harmful particles stay at safe levels.

– Industrial Wastewater Cleaning: Sumps, Pits, and Trenches

Shutting down provides the perfect opportunity to clean pits, sumps, and trench systems that gather production waste. Proper cleaning reduces the risk of backups and helps wastewater treatment systems continue operating efficiently.

How to Execute Your Industrial Cleaning Plan Safely and Effectively

Each step in your industrial cleaning program must prioritize safety and be performed with accuracy, including:

– Energy Isolation: There must be no exceptions to lockout/tagout procedures. It is important to check, confirm, and reconfirm zero-energy states, and every step should be written down in detail to make a clear, traceable record of safety.

– Confined Space Entry: Before anyone enters a confined space the air must be tested, ventilation confirmed, and conditions continuously monitored. Only trained personnel are permitted entry, and attendants and rescue capabilities must be available.

– High-Pressure or Abrasive Cleaning: Hydroblasting, pressure washing, and abrasive cleaning; none of these belong in untrained hands, as they are high-energy, high-risk tasks that demand skill and discipline. The difference between safe practice and disaster often comes down to small choices: proper guarding in place, awareness of the fire line at every step, and the simple but essential act of wearing a mask.

– Waste Segregation and Disposal: Make sure that any hazardous waste, universal waste, and used oil are all clearly labeled. Logs should be updated daily to reflect exactly what’s being stored and where. And the storage areas themselves? They must line up with every single regulatory requirement in place, leaving no room for guesswork or shortcuts.

Let The Experts Take Care of Your Summer Shutdown

Summer shutdowns create a rare break in production, offering an ideal opportunity to reset equipment, complete repairs, and prepare for the next operational cycle.

For more than thirty years, Environmental Remedies has stood alongside facilities throughout the Southeast, building industrial cleaning programs that carry the weight of environmental care.

When summer shutdown planning hits your calendar, make industrial cleaning a top priority. Bring a proven partner with decades of experience in industrial cleaning services to ensure safety, compliance, and performance. Call 1-404-627-5931 to schedule your industrial cleaning consultation today.

Frequently Asked Questions

Q: What is industrial cleaning?

A: Industrial cleaning refers to the deep cleaning of machinery, systems, and production areas in manufacturing or processing facilities to maintain safety, compliance, and performance.

Q: Why is summer shutdown the best time for industrial cleaning?

A: Shutdowns allow cleaning crews to safely access equipment and hard-to-reach areas without disrupting operations.

Q: What areas are most important to clean during a shutdown?

A: Focus on overhead surfaces, machinery, cooling towers, HVAC systems, and wastewater pits.