Industrial wastewater treatment rarely fails in the middle of a calm week; problems show up when production shifts, a washdown dumps a batch, or a storm pushes flow past what yesterday’s settings could handle.

Facilities that rely on industrial vacuum services often see that pattern first because vacuum trucks reveal what’s accumulating in sumps, trenches, and equalization zones before lab numbers start drifting. Solid planning keeps treatment steady; industrial cleaning and plant maintenance support that stability, especially when wastewater changes by hour, shift, or season.

Discharge Pathways Change The Rules That Apply To The Same Water

Regulatory expectations start with a deceptively simple question: where does the water go?

Facilities that discharge to surface waters generally operate under a permit framework tied to effluent limits and receiving-water protections.

Facilities that send wastewater to a publicly owned treatment works face a different framework shaped by pretreatment requirements, including prohibitions meant to prevent “pass through” and “interference” at the municipal plant. Federal pretreatment rules describe prohibited discharges for users connected to a POTW, and the core idea is straightforward: pollutants can’t disrupt treatment operations or slip through untreated.

Treatment obligations can tighten further when national, technology-based standards apply. EPA’s effluent guidelines describe wastewater discharge standards developed on an industry-by-industry basis and built around treatment and control technology performance rather than receiving-water impacts.

That distinction matters because a facility can “treat” wastewater and still miss an applicable standard if the treatment approach is mismatched to the category, pollutant mix, or discharge pathway.

Operationally, that regulatory split changes the work inside the fence line. Direct discharge programs often center around consistent effluent quality over time. Indirect discharge programs add another pressure point: the municipal plant’s tolerance for spikes. Slug loads, cleaning cycles, and batch dumps often create the exact conditions a pretreatment program tries to prevent.

Characterization Turns Wastewater From A Mystery Into A Manageable System

Strong programs treat characterization as engineering intelligence, not paperwork. Industrial wastewater varies because operations vary; a single site may run multiple products, switch chemistries, cycle cleaning routines, and fluctuate production volume. Those shifts create “process fingerprints” that define what treatment can realistically achieve.

A helpful way to think about characterization is to focus on treatability drivers rather than lab minutiae:

Flow and variability patterns shape whether equalization is a luxury or a necessity.

Solids, oils, and grease loadings determine how hard downstream steps have to work.

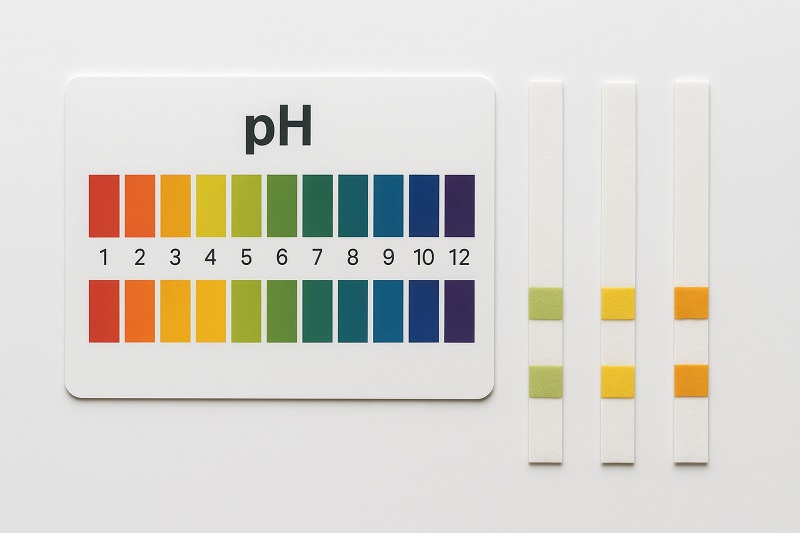

pH swings and reactive chemistry influence corrosion risk, safety controls, and chemical demand. Toxicity or inhibition potential can undermine biological steps quickly, even when average numbers look fine.

Facilities that lean on industrial vacuum services can tighten this picture faster because physical accumulation tells a story that samples sometimes miss. Sludge buildup in a pit, scale in a trench, or oily solids in an interceptor often indicate what treatment sees during the spikes that upset performance. Vacuum trucks paired with routine sampling create a practical feedback loop: remove what’s accumulating, measure what remains, and track how operations change the profile.

Treatment failures tend to appear at the edges of operations; startup and shutdown periods, washdowns, maintenance drains, and batch releases produce short events that punch above their weight. Pretreatment enforcement concepts explicitly focus on preventing interference and pass-through, which is another reason spikes matter more than comfortingly stable averages.

Treatment Trains Hold Up Better Than Single Technology Promises

Industrial wastewater treatment works best as a train of steps; each stage protects the next one.

Front-end physical separation often does the unglamorous work that keeps the rest of the process stable.

Screening, settling, skimming, and equalization help manage solids and oils that can foul equipment or consume chemicals. Regular industrial cleaning of sumps, trenches, and equalization structures reduces surprise loadings that show up as sudden turbidity jumps, clogged lines, or erratic pH readings.

Chemical steps become the workhorse when wastewater contains constituents that won’t behave biologically or physically. Metals, emulsified oils, and non-biodegradable constituents often require precipitation, coagulation, oxidation, or other reactions that shift pollutants into a removable phase.

Performance depends on wastewater chemistry and the surrounding matrix, so characterization and jar testing often save real money by preventing chronic overdosing and underdosing. Biological treatment performs well when biodegradable organics dominate, yet sensitivity to toxicity and shock loads becomes the limiting factor for many industrial streams.

Equalization, upstream solids management, and disciplined operating practices protect biology from the sudden events that can knock it off balance for days. Polishing steps often appear when limits are tight or reuse goals drive performance. Membranes, adsorption, ion exchange, and advanced filtration can help, though the operational tradeoff is rarely hidden: many polishing methods separate contaminants rather than destroy them, creating a concentrated residual that still needs a plan.

PFAS highlights that reality. Many PFAS approaches rely on separation such as adsorption, ion exchange, and membranes; good removal can still leave a concentrated brine or spent media stream that becomes the real handling challenge. EPA’s effluent guidelines program has emphasized ongoing work to assess opportunities to limit PFAS discharges across industrial categories, which signals rising attention in industrial wastewater programs.

Residuals And Liability Stay In The Picture After The Water Looks Clear

Wastewater treatment shifts contaminants somewhere; water gets cleaner, yet secondary waste streams grow. Sludge, filter cake, spent media, brines, and concentrates often carry the pollutants treatment removed. Disposal and classification choices can shape total project cost as much as treatment chemistry does.

EPA’s hazardous waste framework is the anchor for understanding that risk. Hazardous waste can be identified through listed wastes or through characteristics; the EPA describes four hazardous waste characteristics: ignitability, corrosivity, reactivity, and toxicity. The underlying regulatory backbone for hazardous waste identification sits in 40 CFR Part 261.

Planning around residuals changes day-to-day operations. Routine solids removal can protect treatment performance and reduce emergency events. Industrial vacuum services support that approach by keeping pits, sumps, and collection points from becoming surprise reservoirs that dump concentrated loads at the worst possible time.

Plant maintenance ties it all together because valves, pumps, containment, and monitoring points decide whether the system runs smoothly or lurches from one cleanup to another. For many facilities, the practical question becomes simple: would operations rather manage solids on a schedule, or during an upset? Scheduled removal, predictable profiling, and consistent handling often reduce both compliance anxiety and unplanned downtime.

Industrial Vacuum Services Support Wastewater Programs That Need Fewer Surprises

A treatment program improves quickly once wastewater stops being an intermittent crisis and becomes an operational system with feedback.

Industrial cleaning keeps collection infrastructure functional; vacuum trucks remove accumulated solids and liquids before spikes hit; plant maintenance keeps controls and conveyance reliable; industrial vacuum services connect those pieces so treatment steps receive steadier influent and produce more consistent outcomes.

Industrial Vacuum Services That Make Wastewater Problems Easier To Solve

Operations don’t need another report to read; steady performance comes from removing the surprises that build up quietly in pits, trenches, and tanks. Environmental Remedies can help align wastewater treatment goals with practical field execution, including characterization-informed cleanouts, coordinated hauling, and support that fits real production schedules.

Talk with Environmental Remedies about an approach that targets the accumulations and spikes most likely to trigger upsets, so the treatment train remains stable as operations change.

Frequently Asked Questions

1. What is industrial wastewater treatment?

Industrial wastewater treatment is the process of removing contaminants from water generated by manufacturing, processing, cleaning, or production activities before discharge or reuse. Unlike municipal wastewater, industrial water treatment must address site-specific pollutants such as oils, metals, solvents, suspended solids, and chemical byproducts. Effective industrial wastewater treatment typically involves multiple stages—physical separation, chemical treatment, and sometimes biological processes—designed to meet discharge permits and environmental compliance requirements.

2. How does industrial wastewater treatment differ from municipal treatment?

Municipal systems primarily treat domestic sewage with relatively consistent characteristics. Industrial wastewater treatment, however, must handle variable flows, complex chemistries, and higher-strength contaminants. Facilities often need customized treatment trains to address metals, pH swings, emulsified oils, or toxic compounds. Because discharge standards may vary by industry category and receiving system, industrial treatment programs require ongoing characterization, monitoring, and operational flexibility to remain compliant.

3. Why are industrial vacuum services important for wastewater programs?

Industrial vacuum services support wastewater treatment by removing accumulated solids, sludge, oils, and liquids from pits, trenches, and equalization tanks before they cause operational upsets. When buildup is left unmanaged, sudden releases can overwhelm treatment systems and lead to discharge exceedances. Routine vacuuming creates more stable influent conditions, improves system efficiency, reduces emergency cleanouts, and supports wastewater compliance efforts by minimizing unexpected spikes in pollutant loading.

4. What regulations apply to industrial wastewater treatment?

Regulatory requirements depend on discharge pathways. Facilities discharging to surface waters typically operate under NPDES permits governed by federal and state regulations. Indirect dischargers sending wastewater to publicly owned treatment works must comply with pretreatment standards under 40 CFR Part 403. Additional industry-specific effluent guidelines may apply. Compliance requires consistent monitoring, reporting, and documentation to demonstrate that discharge limits and prohibited pollutant standards are met.

5. What happens to sludge and residuals from industrial wastewater treatment?

Treatment processes transfer contaminants from water into secondary waste streams such as sludge, filter cake, spent media, or concentrated brines. These residuals must be properly characterized to determine whether they meet hazardous waste criteria under federal regulations like 40 CFR Part 261. Disposal planning is a critical part of industrial wastewater treatment programs because improper handling of residuals can create liability, additional regulatory scrutiny, and increased operational costs.