Vacuum boxes offer municipal facilities a powerful alternative to traditional sludge removal—especially when safety, compliance, and cost are top priorities. Sludge never stops. It builds day after day, and if you let it sit, costs climb, hazards grow, and compliance can slip fast.

Most cities size up two paths for handling and removal: vacuum boxes or traditional sludge methods. Both are common, but they play out very differently when it comes to safety, cost, and the moving parts on-site.

If you’re planning routine maintenance or mapping a long-term program, it’s important to understand those tradeoffs. Get the right fit for your plant, stay inside the rules, and keep budgets steady while the system keeps running.

What Are Vacuum Boxes?

Vacuum boxes are sealed roll-off containers that work with suction to pull in liquid or semi-solid sludge, lock it down, and move it off-site without any spillage.

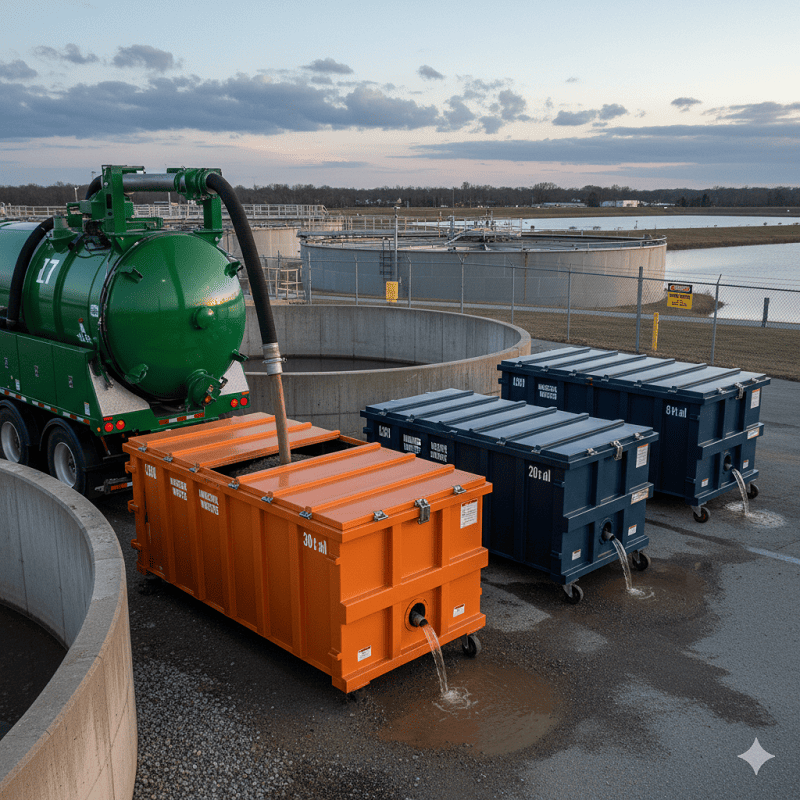

Most units fall between 8 and 30 cubic yards, and you can stage them on-site, fill them as work progresses, then haul them when they’re topped off. Many models add smart touches like dewatering liners or drainage ports so liquids separate from solids and the load becomes lighter and easier to handle.

Municipal crews lean on vacuum boxes for lagoon cleanouts, digester maintenance, and clarifier projects where volumes can quickly escalate. Portability keeps work moving during outages and emergencies, and staging multiple boxes lets the vacuum truck stay on task instead of sitting idle.

The need is massive, with the EPA estimating nearly 7 million dry tons of biosolids produced in the United States each year. Moving that volume efficiently is a constant challenge, and sealed roll-off options like vacuum boxes remain a practical, cost-conscious way to get material contained, transported, and off-site.

Traditional Sludge Removal Methods in Municipal Services

Conventional sludge management often relies on large, fixed systems or intensive cleanup processes, including centrifuges, belt filter presses, lagoon dredging, and full tank cleanouts. The purpose is straightforward: drive down water content so the material can be transported as a denser, more manageable cake instead of a slurry, ultimately lowering hauling volumes and long-term costs.

In practice, centrifuges generally push solids content into the 20 to 30% range, while belt presses usually deliver around 18 to up to 25%. That drier material lowers disposal weight significantly, but the process requires higher capital investment, chemical inputs, and energy consumption.

Lagoon dredging, another traditional option, involves mobilizing specialized equipment and often requires workers to enter or work close to confined spaces, which increases safety considerations.

Safety Considerations for Municipal Teams

Managing sludge removal requires far more than simply moving material from one location to another; municipal teams must address worker exposure to confined spaces, toxic gases, and noise hazards in a way that protects employees while still keeping projects on schedule.

Confined Space Risks

Tank and digester cleanouts frequently fall under OSHA’s permit-required confined space standards. Entry into these spaces can place workers at risk from toxic gases, engulfment, and restricted exit routes. Municipal crews handling such projects must meet added layers of training, documentation, and compliance obligations before work can even begin.

Vacuum boxes cut down on the need for workers to physically enter confined spaces, allowing sludge to be pumped directly into containers from the outside. Fewer entries mean safer working conditions and a simplified compliance program.

Hydrogen Sulfide Hazards

Hydrogen sulfide (H₂S) often develops in sludge-heavy environments, and while invisible, it poses severe danger. Concentrations above 100 ppm are classified as immediately dangerous to life and health (IDLH).

NIOSH sets strict limits, capping exposure at 10 ppm over a 10-minute span. Continuous monitoring is essential for both vacuum-based and manual methods, but vacuum systems lower the risk by cutting back on how often workers are directly exposed.

Noise Exposure

Vacuum trucks, pumps, and compressors can produce noise levels above OSHA’s 85 dBA threshold for hearing conservation programs. Traditional dewatering rooms are generally quieter but require operators to remain near rotating machinery for extended periods.

In either scenario, noise monitoring and protective equipment should be part of municipal safety protocols.

Environmental and Regulatory Factors That Shape Sludge Handling

Every approach to sludge handling is governed by a framework of environmental and transportation rules that cover everything from how liquid decant is discharged to how biosolids are managed under EPA Part 503 to how roll-off containers must be secured in transit.

NPDES and Decant Management

Any liquid released from sludge handling, such as filtrate from a dewatering box, must be managed under a National Pollutant Discharge Elimination System (NPDES) permit if discharged to surface waters.

If routed to a sanitary sewer, local pretreatment requirements apply. Ignoring this step can result in significant fines.

Biosolids Regulation

EPA Part 503 sets the ground rules for how biosolids are land applied or disposed of. No matter how you remove the material, with vacuum boxes or traditional gear, you still have to meet pollutant limits, achieve vector attraction reduction, and hit the required pathogen standards to stay compliant.

Transport and Securement

Vacuum boxes fall under the roll-off container category, so they have to travel closed and secured. Lids shut. Doors latched. Gaskets seated. No leaks, no loose parts, no surprises once the truck is rolling.

The Commercial Vehicle Safety Alliance sets the playbook for how those containers get tied down. If you hire a hauler, ask for proof they follow CVSA securement guidance, check rated tie-downs and attachment points, and confirm pre-trip inspections are part of the routine.

Build those requirements into contracts and spot-check at pickup so every load stays compliant and safe.

Operational Benefits of Vacuum Boxes for Municipal Facilities

Vacuum boxes offer municipalities a combination of flexibility, staging efficiency, and reduced risk exposure that makes them particularly valuable in maintenance projects, seasonal cleanouts, and unexpected surges in sludge volume.

Flexibility

Vacuum boxes slot in easily when work is stop and start or truly urgent. You can stage a bank of them on site, keep them sealed and ready, pull suction as needed, then swap full units with almost no wait.

That flexibility pays off during clarifier cleanouts, sudden overflow response, and seasonal lagoon dredging, where volumes surge and schedules shift. With a small fleet on the ground, crews keep moving, vacuum trucks stay productive, and operations remain safe and compliant.

Reduced Downtime

Vacuum trucks can unload straight into a staged box and jump back on the hose within minutes, instead of burning time on an off-site haul.

That one-step transfer trims idle time, keeps crews productive, and cuts delay costs, which is a big win in tight urban jobs where traffic, permits, and long queue lines stretch every turnaround.

Safety Advantages

Vacuum boxes line up with OSHA’s hierarchy of controls by cutting down on confined space entries and reducing hands-on sludge handling.

As engineering controls, they capture and contain material at the source so exposure drops before it reaches workers, rather than relying mainly on personal protective equipment.

When Traditional Sludge Removal Makes Sense

Facilities dealing with steady, high-volume sludge output often benefit more from installing permanent dewatering systems. Centrifuges and belt presses are capable of handling thousands of gallons daily, with reliable chemical dosing and manageable sidestreams.

For larger municipal services with consistent flow, these traditional dewatering methods usually bring down the long-term cost per dry ton, making them more economical than hauling massive volumes of slurry in containers.

Comparing Vacuum Boxes with Traditional Approaches

| Factor | Vacuum Boxes | Traditional Removal |

| Confined space entry | Often avoidable | Frequently required |

| Transport | Sealed, roll-off containers | Dewatered cake hauled |

| Throughput | Best for intermittent or variable projects | Ideal for continuous, high-volume flows |

| Regulatory focus | Container management, NPDES for decant | Part 503 biosolids, sidestream permits |

| Noise exposure | High near trucks | Lower, but rotating equipment risks |

| Capital cost | Lower, temporary | Higher, permanent systems |

Improving Municipal Services Through Efficient Sludge Removal

Municipal facilities evaluating sludge removal strategies often compare vacuum boxes against permanent dewatering systems, with the right choice hinging on factors like sludge volume, project frequency, and regulatory obligations.

Vacuum boxes continue to gain traction across municipal services due to their safety advantages and flexibility. For over three decades, Environmental Remedies has partnered with municipal teams across the Southeast, shaping strategies to fit the distinct needs and conditions of each plant. Request a quote today and learn more about how our expertise can improve your current operations.

Frequently Asked Questions

Q: What is a vacuum box, and how does it work?

A: A vacuum box is a sealed roll-off container designed to collect and transport liquid or semi-solid sludge using suction. These boxes lock in material securely, preventing spills, and often include drainage ports or dewatering liners to simplify handling.

Q: When should municipal facilities use vacuum boxes instead of traditional sludge removal methods?

A: Vacuum boxes are ideal for intermittent, high-volume, or emergency projects, such as clarifier cleanouts, digester maintenance, or lagoon dredging. They reduce downtime, limit confined space entry, and provide greater flexibility than fixed dewatering systems.

Q: Are vacuum boxes compliant with EPA and OSHA regulations?

A: Yes, vacuum boxes help facilities meet EPA Part 503 biosolids rules and OSHA standards by minimizing exposure to confined spaces, hydrogen sulfide gas, and noise. They must also follow proper container securement rules under CVSA guidelines during transport.