Every production facility deals with dust, residue, and spills that build quietly during daily operations. Plant safety problems rarely begin with dramatic failures; they start with material left behind on floors, beams, pits, and equipment. Industrial vacuum services directly address those risks at the source.

In the early stages of industrial cleaning, these services remove hazardous materials without re-suspending them into the air, supporting safer plant maintenance and reducing conditions that lead to fires, injuries, or regulatory findings. As plants pursue better safety performance, industrial vacuum services increasingly sit at the center of that effort.

Where Industrial Vacuum Services Fit Into Modern Plant Operations

Industrial vacuum services address contamination and hazard control at a level far beyond ordinary housekeeping tasks.

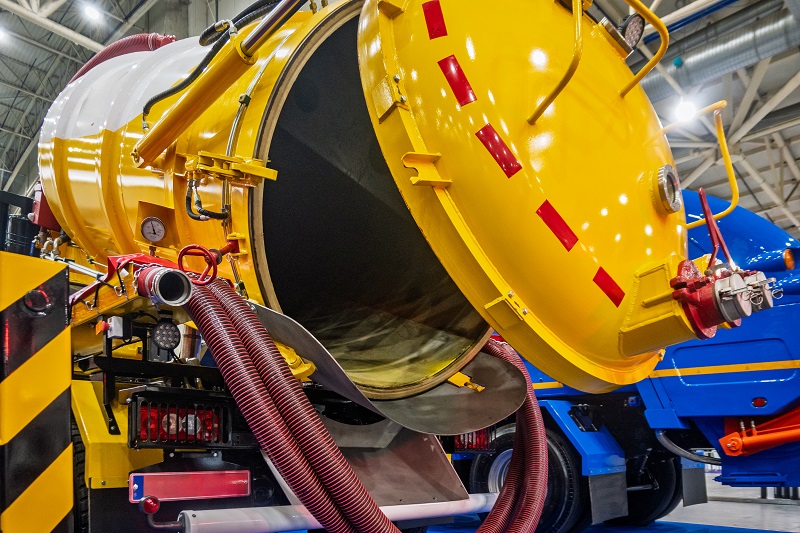

Engineered systems capture powders, dusts, liquids, and sludges while controlling static electricity, ignition sources, and airborne release. Vacuum trucks and specialized portable units enable the removal of material from confined areas, elevated structures, and production zones without causing contamination.

Dry sweeping or compressed air often redistributes dust, increasing exposure and ignition risk. Industrial vacuum services pull material into sealed systems, filter exhaust air, and support compliant handling once it leaves the process area.

That difference explains why regulators and safety professionals consistently point to vacuum-based industrial cleaning as a preferred approach in hazardous environments.

Combustible Dust Control Drives High Consequence Risk Reduction

Combustible dust incidents rank among the most severe industrial accidents because small disturbances can escalate rapidly.

Dust accumulations resting on surfaces can become fuel for secondary explosions once dispersed into the air. Federal investigations into catastrophic events, including food processing and bulk material facilities, repeatedly identify poor housekeeping as a contributing factor.

Industrial vacuum services reduce that potential risk by removing dust without creating any clouds.

Conductive hoses, grounded components, and equipment designed to keep dust away from motors lower ignition potential during cleaning activities. Vacuum trucks extend that capability to large-scale cleanups, outage work, and hard-to-reach areas such as rafters, conveyors, and dust collector rooms.

Facilities relying on traditional industrial cleaning methods often struggle to maintain safe accumulation levels over time. Industrial vacuum services support routine and event-driven cleaning without adding new hazards to the environment.

Airborne Exposure Control Protects Workers Beyond Visible Dust

Many exposure hazards go unnoticed because they are not visible during normal, day-to-day operations.

Fine particulate matter, including respirable crystalline silica and other toxic dusts, can remain suspended long after sweeping ends. Regulatory standards restrict dry sweeping when it raises exposure levels, pointing toward vacuuming with effective filtration as a safer alternative.

Industrial vacuum services capture fine material directly at the surface and filter exhaust air before release. That approach limits recontamination and reduces repeated cleaning cycles.

Plant maintenance teams benefit from fewer exposure-driven interruptions, and workers experience lower inhalation risk during and after cleanup activities.

Vacuum trucks with the right filters can handle a lot of material while keeping it contained, meaning that production areas can get back to work faster after maintenance or spills.

Slip and Trip Hazards Remain a Leading Injury Source

Walking-working surface hazards are responsible for hundreds of thousands of injuries annually across industrial environments.

Fine powders behave like ball bearings underfoot, while wet sludges and spilled product reduce traction on smooth floors. Safety programs often address these risks procedurally, yet physical removal remains essential.

Industrial vacuum crews remove dry powders, wet residues, and liquid spills without smearing them across walkways. Containment stays tight. Foot traffic stays clean. Vacuum methods cut down on improvised mopping that tracks hazards into adjacent areas and keeps cleanup controlled from start to finish.

As part of ongoing plant maintenance, vacuum-based removal helps keep aisles, platforms, and access points safer throughout the facility.

Housekeeping Programs Depend on Consistent Execution

Certain industries operate under explicit housekeeping requirements that mandate documented cleaning methods and defined response thresholds.

Grain handling standards provide a clear example, requiring written programs and immediate action when dust accumulations exceed safe limits. Similar expectations appear across many manufacturing sectors during audits and inspections.

Industrial vacuum services scale the work. Vacuum trucks handle rapid response during peak runs, shutdowns, and seasonal surges. Portable units tackle routine buildup in tight, elevated, or confined spots without spreading debris.

Together, these tools transform housekeeping from an aspirational goal into a repeatable safety control integrated into plant maintenance planning.

Spill Response and Environmental Protection Demand Precision

Spills of oil, chemicals, or process materials raise safety risks and environmental liabilities in the same breath. Regulations on spill prevention and waste management demand rapid containment, controlled cleanup, and proper handling of recovered material.

Capture it. Label it. Store and dispose of under all applicable rules and regulations. Simply put, compliance protects people, limits impact, and keeps operations out of trouble.

Industrial vacuum services recover spills quickly using sealed containment rather than sweeping or washing material into drains. Vacuum-based cleaning keeps contamination from spreading and makes waste handling straightforward.

Material moves from the sealed line to the sealed container. Labels, manifests, and the chain of custody stay clean and simple when the recovered load enters the waste stream.

For larger spills, bring in vacuum trucks. They pull down free liquids fast, cut environmental exposure, and help the site return to normal operations sooner. Faster capture. Fewer touch points. Better compliance.

Outsourcing Industrial Vacuum Services Reduces Hidden Risk

In-house crews often lean on tools that weren’t built for hazardous cleanup. Wrong vacuums, nonconductive hoses, weak filtration. Add static, sparks, and aerosols, and you’ve just raised the risk of ignition and exposure.

Specialized industrial vacuum teams close those gaps. Equipment is matched to the hazard class. Operators are trained. Procedures align with regulations. Vacuum trucks and portable units roll in ready to work, cutting uncertainty and controlling high-risk cleaning from first capture to final container.

For many facilities, outsourcing removes a layer of operational risk while strengthening overall plant maintenance performance.

Industrial Vacuum Services Support Safer, More Predictable Operations

Identifying and eliminating hazards before they cause incidents significantly improves plant safety as a whole.

Industrial vacuum services get rid of flammable dust, lower the risk of breathing in harmful particles, reduce slipping risks, and help manage spills in a way that follows all applicable safety rules

Industrial cleaning performed through vacuum systems integrates smoothly into plant maintenance schedules while delivering measurable safety outcomes.

As facilities face increasing scrutiny and production demands, industrial vacuum services provide a practical path toward safer, cleaner operations.

Industrial Vacuum Services and Plant Safety Outcomes That Last

Safer plants start with controlled environments where hazards don’t quietly accumulate. Industrial vacuum services give facilities a proven way to manage dust, spills, and residues while supporting compliance and operational stability.

Environmental Remedies brings decades of experience delivering industrial cleaning through advanced vacuum trucks and specialized systems. Reach out today to discuss how our industrial vacuum services can strengthen plant safety and support long-term performance.